Instant Conveyor Belt Repair Kit,Quickly repair conveyor belt wear

Product Description :

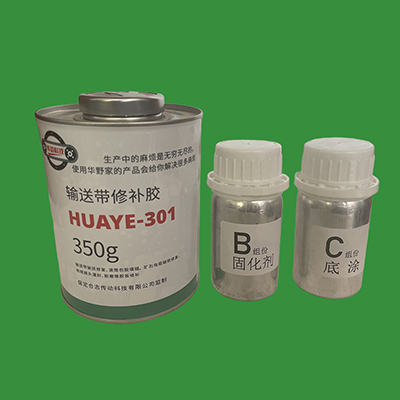

This product is a high-strength , wear-resistant , and fast-curing rubber repair agent composed ofthree components : A ( main adhesive ) , B ( curing agent ) , and C ( base agent ) . Mainly used for rapierepair of surface damage and large-scale wear of various conveyor belts , sealing of conveyor beltcold vulcanization joints , coating of belt buckles , repair of wear-resistant pipeline lining rubberdamage , and can also be used for cable cold repair and repair of various rubber products

Product features

- High wear resistance 2-3 times that of ordinary conveyor belts

- High strength , high elongation , and good toughness

- Fast solidification , suitable for large-scale repair

Polishing :

Use a tungsten steel polishing disc to polish and coarsen the surface of the brokenrubber of the conveyor belt . Pay attention to preventing polishing or burning during polishing .Cleaning and drying : Carefully clean the surface and treated residue with a cleaning agent untilthere is no dirt , and then air dry or heat dry .

Coating agent : Apply a layer of rubber primer evenly on the treated rubber surface , and dry it atan ambient temperature of 25 ” C for about 15 minutes .

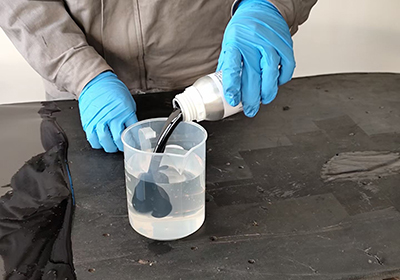

Mixing : Mix the adhesive according to a weight ratio of A : B-20 : 1 and stir thoroughly and quicklywithin 1 minute . Use up within the operating period and mix as needed.

Application : Use a short bristle brush or scraper to apply the prepared adhesive to the treatedrubber surface , with a coating thickness controlled within 2mm

Precautions :

1 ) sealed , and stored in dry conditions

2 ) The construction site must maintain good ventilation.

Storage period : 12 months